With our expertise and experience, we offer sealing, protection, and cushioning profiles that meet all the needs of the industrial sector.

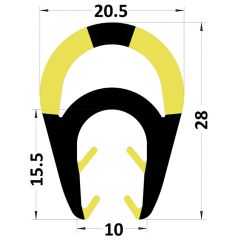

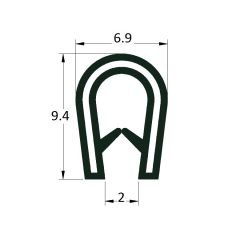

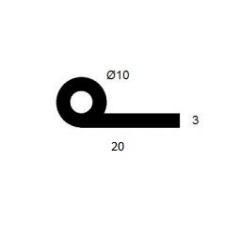

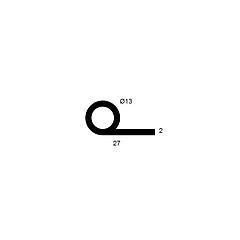

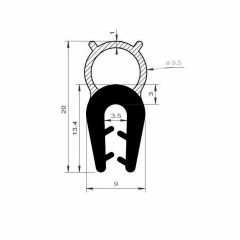

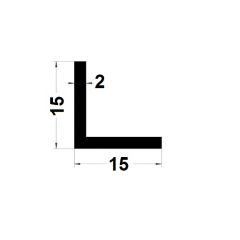

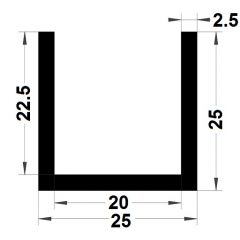

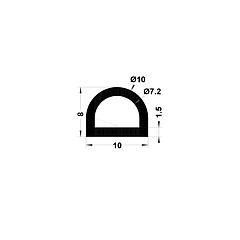

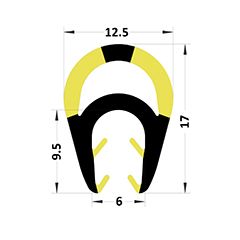

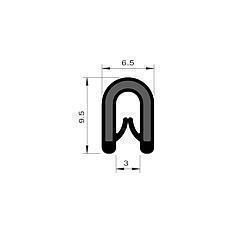

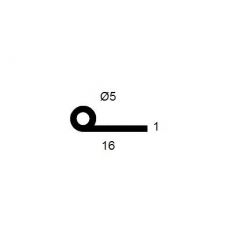

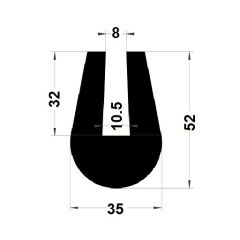

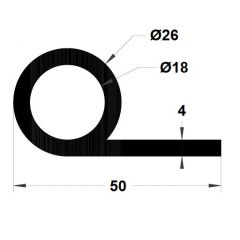

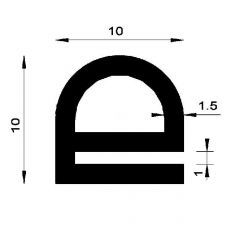

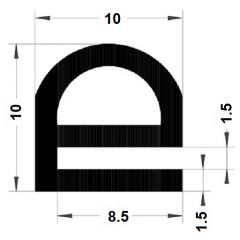

We offer metal sheet protective profiles with steel, stainless steel or POM reinforcement, U-seals without reinforcement, bubble-sided gaskets with clamping band, U-profile with sealing lip, P-shaped profiles, E-shaped profiles, tubular seals with adhesive, edge protection profiles, dock fenders, tank seals and gaskets for trash compactor...

All these types of seals are designed to meet specific needs, such as ensuring total sealing, providing optimal and efficient protection, or dampening certain shocks. It is important for you to clearly identify the type of seal you need, based on its intended use, as these seals do not all have the same characteristics.

Some of our profiles are extruded with materials that meet the EN 45545-2 and UL 94 HB fire and smoke standards.

Our products are durable. The resistance to acids and bases as well as to hydrocarbon sprays depends on the materials chosen. Our materials are non-marking.

Our TPE seals are 100% recyclable (EU 2002/95/EC: RoHS & 2000/53/EC: ELV)

To assist you in your product search, we have listed below some frequently asked questions along with their respective answers.

We hope that these clarifications will further guide you in finding the right solutions for your needs.

What is a PTFE seal?

A PTFE seal, also known as a Teflon seal, is a type of sealing joint used in various industrial applications. Made from PTFE (polytetrafluoroethylene), a heat and chemical-resistant material, it provides excellent sealing performance in extreme conditions. PTFE seals are smooth, non-stick, and durable, making them suitable for piping systems, valves, pumps, and fittings. They resist high temperatures, aggressive chemicals, and corrosive fluids. Currently, we do not sell them on our website.

How to create a proper sealing gasket? Which type of industrial sealing joint?

If you are wondering how to apply gaskets in the industrial sector, there you are the steps to follow. First, ensure that the surface to be sealed is clean, dry, and free from dust, grease, or any other impurities. You can use a suitable cleaner to clean the area if necessary. After selecting the appropriate sealing material for your needs, cut the sealing material to the desired size using scissors, a knife, or a suitable tool. You can find a specifically designed cutting plier for joints on our website by clicking here. Make sure the cut is precise and matches the area to be sealed. Place the cut sealing material onto the sealing area. Ensure it is properly positioned and fitted. If needed, on our website, you can find adhesive-backed seals or even adhesives suitable for our product materials (TPE or silicone) by clicking here. Then, apply uniform pressure to the sealing joint to ensure it adheres firmly to the surface. If you have used an adhesive, let the sealing joint dry according to the manufacturer's instructions. Avoid handling the sealed area during this time to ensure proper adhesion. Finally, once the adhesive applied to the sealing joint is completely dry, visually check if it is properly applied and forms a tight barrier. If any defects are observed, you may need to redo the joint by following the previous steps again.

What type of industrial gaskets/seals?

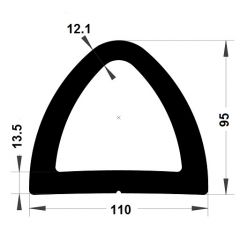

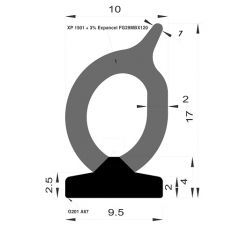

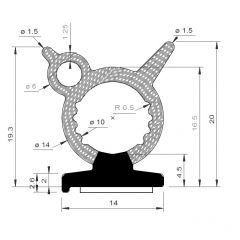

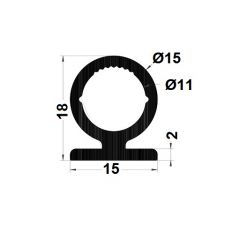

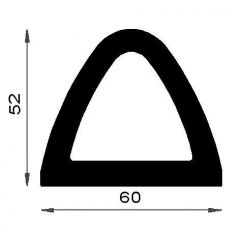

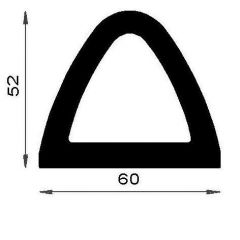

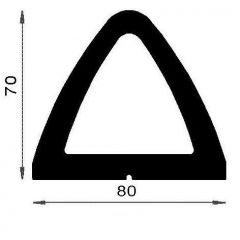

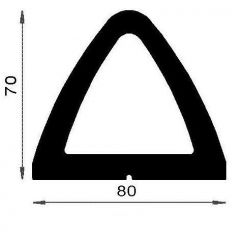

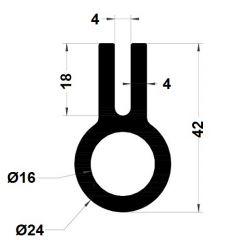

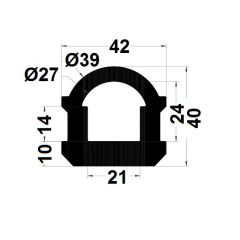

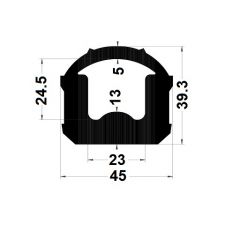

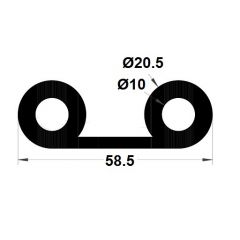

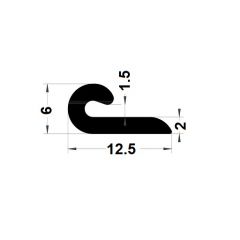

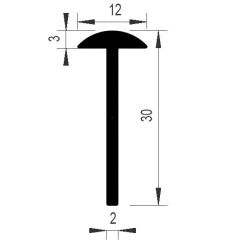

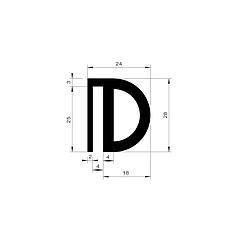

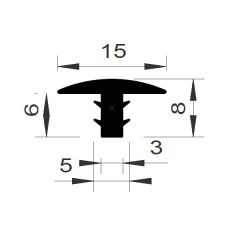

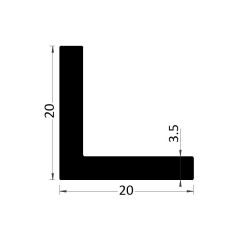

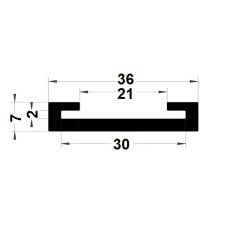

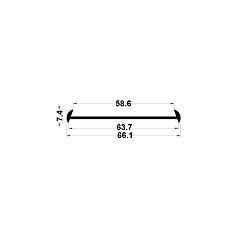

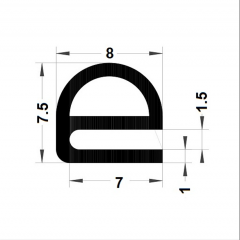

If you're wondering about the different types of industrial gaskets and seals, you've come to the right place. On this page, you'll find our offering for sealing solutions in the industrial sector. Our range includes sheet edge joints (or U-shaped joints) in various shapes and sizes, with or without steel reinforcement, with or without lips, and with or without foam gaskets. We also provide P-shaped joints (or musical note joints), adhesive-backed tubular joints, E-shaped joints, edge protection joints (or C-shaped joints), container and waste compactor joints, tank joints, corner protectors, shock absorbers, delta guards, dock guards, and bumpers. These are the products we believe are most useful for your industrial applications. However, if you can't find the specific product you're looking for in our catalog, you can have custom profiles produced through the Prodex website by clicking here.

What is a dock guard? What is a fender?

A dock guard is a device used to protect docks, piers, or similar structures from impact with vessels, while also protecting the vessels themselves during docking or mooring operations. It is designed to absorb and disperse the kinetic energy generated when a boat collides with the dock structure. Dock guards can replace boat fenders, which act as protection and shock absorbers, and are attached directly to the boat's hull. Dock guards are typically made from resilient materials such as rubber, elastomeric or TPE materials. On our ProfilesMarket website, you'll primarily find TPE guards. These guards are attached to the dock structure and act as a cushion to absorb impacts and prevent damage to both the dock and the boats that may dock there. There are different types of dock guards available, suited to specific dock and maritime traffic conditions. On our website, you'll find delta guards, dock bumpers, protection strips, and circular bumpers. Dock guards are essential for ensuring the safety of port facilities by reducing damages caused by vessel impact forces. They help extend the lifespan of docks, prevent cracks and structural deformations, and ensure safe docking and mooring operations. The selection and installation of dock guards depend on factors such as vessel size, docking speed, tidal variations, and environmental conditions in the port or terminal.

What is a loading and unloading dock?

A loading (or unloading) dock is a specially designed platform that facilitates the transfer of goods between transport vehicles (trucks, trailers, etc.) and storage facilities in a warehouse, factory, or distribution center. It is an area equipped with an inclined ramp that allows trucks to reverse and position themselves level with the dock. This facilitates the loading and unloading of goods using forklifts, pallet jacks, or other handling equipment. Loading docks are essential for ensuring efficiency and smoothness in the logistics chain, enabling the quick and secure transfer of goods between transportation means and storage facilities.

What is a dock bumper? What are dock bumpers used for?

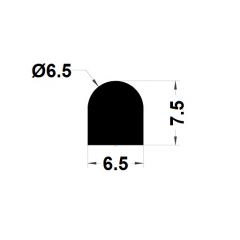

In the context of loading docks, you might wonder how to protect the structure from potential collisions between transport vehicles and the walls of the structure. The solution is to install a dock bumper, also known as a dock buffer, at the end of these docks. These protection and safety devices are typically made of a sturdy material such as TPE or rubber and are designed to absorb shocks when a vehicle reverses and reaches the end of the dock. They help prevent damages to vehicles, dock walls, and handling equipment by reducing the impact of the collision. In addition to their protective function, dock bumpers also serve as visual markers for vehicle drivers when reversing toward the dock. They assist in properly aligning the vehicle with the dock, thereby facilitating loading and unloading operations by ensuring precise positioning. You can find a wide selection of dock protection products on our website.

What is the difference between a rubber edge trim and a U-profile seal?

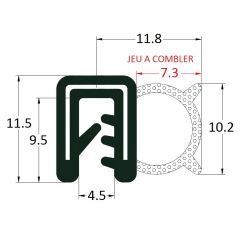

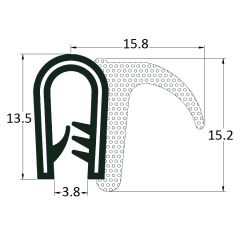

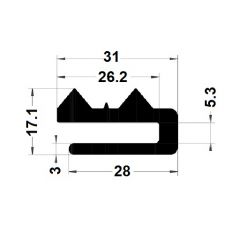

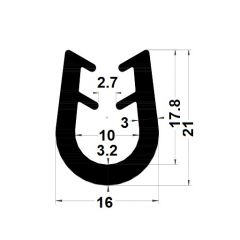

When looking at the products offered by different industrial protection suppliers, you may notice that some of them offer rubber edge trim or metal sheet edge protection, while others offer U-profile seals or U-profiles, and a few others offer clamps. So, what is the difference between an edge trim and a U-profile seal? It turns out that they are quiet the same thing, with the difference being that edge trim are specifically designed to protect metal sheets or similar materials, whereas U-profile seals have the same purpose but can be used for other applications in certain cases. The term "U-profile" simply refers to the shape of these seals. Any seal that takes the form of a U can be called a U-profile seal.

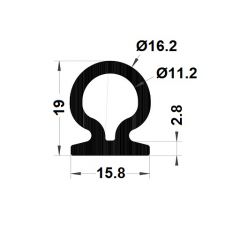

What is the role of a lip seal profile?

The role of a lip seal profile is to provide a tight barrier between two surfaces. This type of seal is often used to prevent fluids, such as liquids or gases, from escaping a space or entering a gap. The lip of the seal is made of a flexible material, such as rubber or TPE, so that it can be flexible as well and seal against the adjacent surface. The lip of the seal is designed to exert pressure against the surface, thereby forming a tight seal. Lip seal profiles are used in various industries for different applications. They are used in industrial machinery and equipment, engines, transmissions, hydraulic and pneumatic systems, pumps, valves, bathrooms (particularly in showers), and many other sectors. They help prevent leaks, reduce friction, protect against dust, contaminants, and moisture, and extend the lifespan and efficiency of components and systems.

What is a SPI gasket?

A SPI gasket, also known as a Spiral Wound Gasket (SWG), is an industrial gasket used for sealing applications. It consists of a V-shaped metal strip (typically stainless steel) and a soft filler material like graphite or PTFE. The metal strip and filler material are wound in a spiral pattern. SPI gaskets are designed to provide effective sealing in high-temperature, high-pressure, and corrosive environments. They are commonly used in industries such as oil and gas, petrochemical, power generation, and chemical processing. The inner and outer rings of a SPI gasket help to prevent collapse and provide additional compression and stability. SPI gaskets are known for their ability to withstand extreme conditions and provide reliable sealing in demanding industrial settings. Currently, we do not sell this kind of gasket on our website.

How to put a gasket on dumpster doors?

To install a gasket on dumpster doors, you can follow these steps. Firstly, make sure that the surfaces of the dumpster doors and the surrounding frame are clean and free from any debris or old adhesive residue. This can be achieved by using a suitable cleaner or solvent. Next, measure the length of the door edges that require sealing and cut the gasket material accordingly. It is essential to choose a gasket material that is compatible with the intended application and can provide the necessary sealing properties. Depending on the specific instructions provided, you may need to apply adhesive to one or both sides of the gasket or directly onto the door edges. Now, carefully press the gasket onto the door edges, ensuring proper alignment and positioning. Start from one end and gradually work your way along the edge, applying firm pressure to ensure good adhesion. If there is excess gasket length, trim it using a sharp utility knife or scissors, being cautious not to damage the gasket or the door surface. Finally, close the dumpster doors and test the seal to ensure proper contact and compression of the gasket. Verify that the gasket provides a tight seal when the doors are closed, thus preventing any leakage.

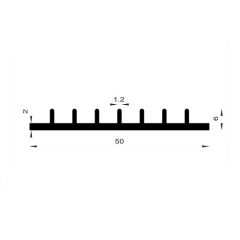

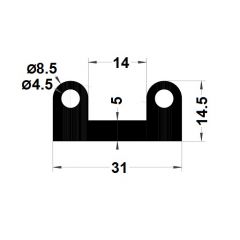

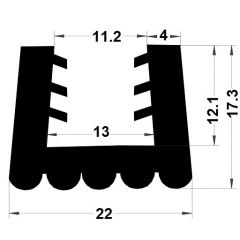

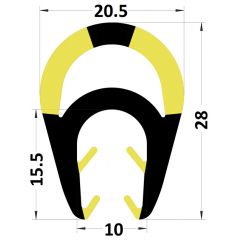

PM29041/F6086 - Shock protective edge protector for I-Beam - Box of 10 lengths€150.42 €125.35PM29041

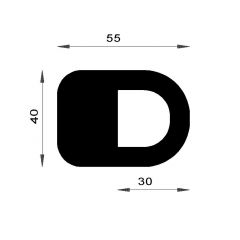

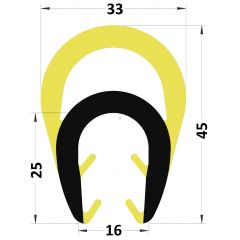

PM29041/F6086 - Shock protective edge protector for I-Beam - Box of 10 lengths€150.42 €125.35PM29041 PM29039/F5216 - Shock protective edge protector for I-Beam - Box of 10 lengths€330.92 €275.77PM29039

PM29039/F5216 - Shock protective edge protector for I-Beam - Box of 10 lengths€330.92 €275.77PM29039